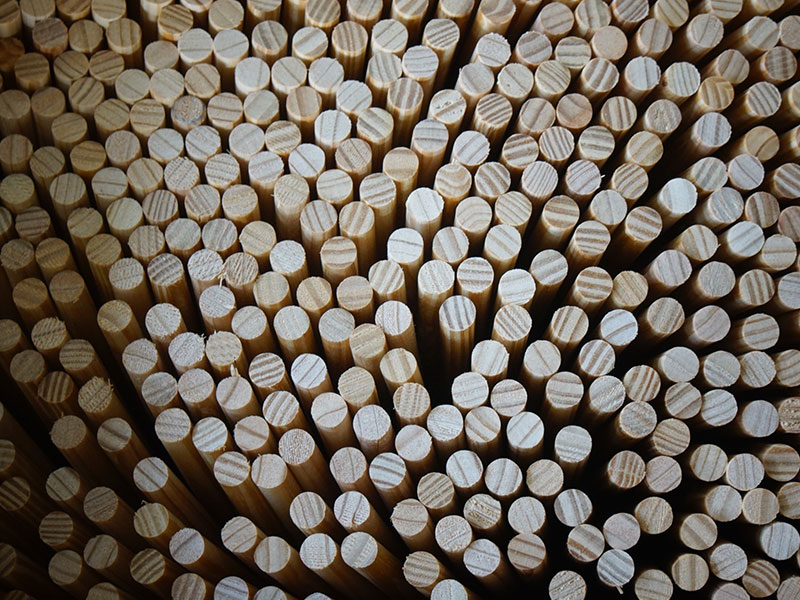

Dowel Manufacturer

As a premier Dowel Manufacturer, we take pride in our commitment to precision and craftsmanship

All diameters, lengths and species are available upon request

While seemingly an unremarkable product, dowels (or houtstokkies) are purposed by all sorts of industries like contractors, mines, carpenters, furniture manufacturers, builders, scientists, gardeners, interior designers, bakers, sign makers, crafters, toymakers, hobbyists, interior designers, landscapers, pet accessory manufacturers and countless other industrial and small enterprises.

Dowels have a myriad of industrial applications but are also employed by DIY & gardening enthusiasts for anything imaginable. And as more and more women are starting to use power tools, dowels are an obvious choice for innovative ideas, because they are lightweight and easy to work with.

Although we can turn any applicable and available timber, our standard dowels are made from quality South African Pine and Saligna, for which we carry the Proudly SA logo.

Dowel Manufacturer

NOTE: In 2021 we changed our business name from Pretoria Dowel Manufacturers to Dowel & Co. (Pty) Ltd.

Because of the global changes in forestation, supply, economics and shipping, we believe that our survival as a timber manufacturer is in the procurement of a constant supply of quality, local timber to be available not only to meet our stock and sales requirements, but to position ourselves to meet any sudden increase in demand. To achieve this, we have joined forces with reputable, local Pine and Saligna timber mills who are committed to sending us a steady supply of clear timber.

Because quality drives our service orientated business, preparation and subsequent processes must be determined meticulously and the elimination of waste product is our constant focus.

While procuring enough quality timber to feed our machines, we must restrict risk in unstable markets, yet at the same time, increase production to stimulate growth by constant re-stocking of our clients’ shelves and finding creative ways to motivate sales.

World-wide forestation laws have tightened up and the result is that fabricators have to think green. Many trees are still juvenile when felled, resulting in smaller sizes entering the manufacturing market and forcing manufacturers to become innovative. Before leaving the mills, timber is cut into standard sizes, and it is up to the manufacturer to determine how best to utilize each size to turn out the optimum number of dowels with the least quantity of off-cuts. Anything not used in the manufacture of a specific dowel is re-thought and re-cycled into other usable products. Shavings and sawdust are sucked into an extraction system and collected in an external silo, from where it is packed and distributed to farmers. This completes the recycling circle, from when a seed is planted in the earth, until the last little bit of sawdust from that tree becomes the compost for the next tree.

Because dowels are light and easy to work with, we encourage the employment of women. Not only do they pay attention to the smaller details, but by employing the mothers, we hope to ensure the care and education of future generations of South Africans.

Dowel Manufacturing Process

Step One

Timber is cut into standard sizes when it leaves the mill and from there we determine how best to utilize each size to turn out the optimum amount of dowels, with the least amount of waste and off-cuts.

Step Two

The machinery and blades used in the manufacture of dowels need precise setting and maintenance. While procuring enough quality timber to feed the machines, we have to restrict risk in an unstable market, yet at the same time, increase production to stimulate growth by constant re-stocking of our clients shelves.

Step Three

Because dowels are light and easy to work with, we encourage the employment of women. Not only do they pay attention to the smaller details, but by employing the mothers, we hope to ensure the care and education of future generations of South Africans.

Step Four

With environmental concerns becoming globally more pressing, we are proud to use a product that is easy to recycle. Our shavings and sawdust is extracted, packed and distributed to farmers for animal use. This completes the recycling circle, from when a seed is planted in the earth, until the last little bit of sawdust from that tree becomes the compost for the next tree.

We work with amazing companies

Build It

Matus

Chamberlain

The Teepee People

Boxa

Active Concepts

Give us a call 082 496 9696 or email lara@activeconcepts.co.za

Hot Pot Paint & Hardware

House of York

House of York is locally produced in Gqeberha, South Africa. We use superior grade timber from local-managed, eco-friendly forests. We produce wooden household products of the highest quality for your home, to suit every household’s need.

Contact us at: houseofyork@eveready.co.za

Lasec

Dowel applications for crafters and hobbyists

Turn basic dowels into pretty and practical home accent with these creative ideas.

- Dowel cat bed

- Dowel bird house

- Dowel dog house

- Dowel bird feeder

- Dowel art

- Bedside table dog bed

- Dowel wall cladding

- Dowel wall art

- Dowel garden trellis

- Dowel shoe storage

- Dowel reel board

- Dowel photo portraits

- Dowel peg wall

- Dowel outdoor swings

- Dowel Macramé hammock

- Dowel coffee table

- Dowel hammock

- Dowel cylindrical furniture

- Dowel Christmas tree

- Dowel cat play bridge